The addition of calcium chloride in the cheese making process can significantly shorten the curd time and increase the strength of the gel, but excessive calcium chloride addition will increase the electrostatic repulsion between micelles and hinder the formation of gel. Calcium addition can significantly increase The soluble and insoluble calcium content in cow’s milk significantly increases the total calcium content in cheese products, but has no significant effect on the basic components of cheese such as protein, fat, moisture, salt content, and pH. The addition of calcium chloride significantly reduces protein hydrolysis It increases the hardness and elasticity of the cheese, and reduces the bitterness of the cheese. In general, calcium chloride is added to the emulsion after being dissolved in water. The current food grade calcium chloride in the market is mainly 77% and 94%. The difference between the two types of calcium chloride is only the calcium chloride content. According to the calculation of calcium chloride produced by Qingdao Jiede Chemical Co., Ltd., the amount of 77% calcium chloride is about 1.5g-26g; the amount of 94% calcium chloride is about 1.06g-21g. Its product performance is the same as that of the international brand CC food®.

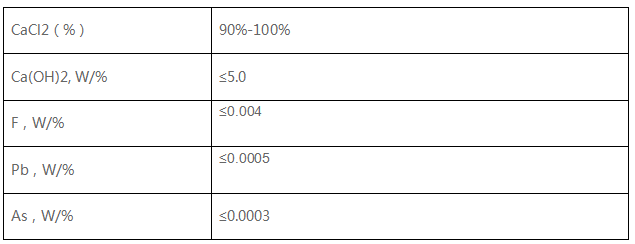

In addition, in use, the following parameters should be paid attention to. According to the FCC’s food-grade calcium chloride requirements, the parameters are as follows

Therefore, while paying attention to food-grade calcium chloride, we should also pay attention to the heavy metal content in it to prevent food safety risks.